- By Vanshika Choudhary

- April 17, 2025

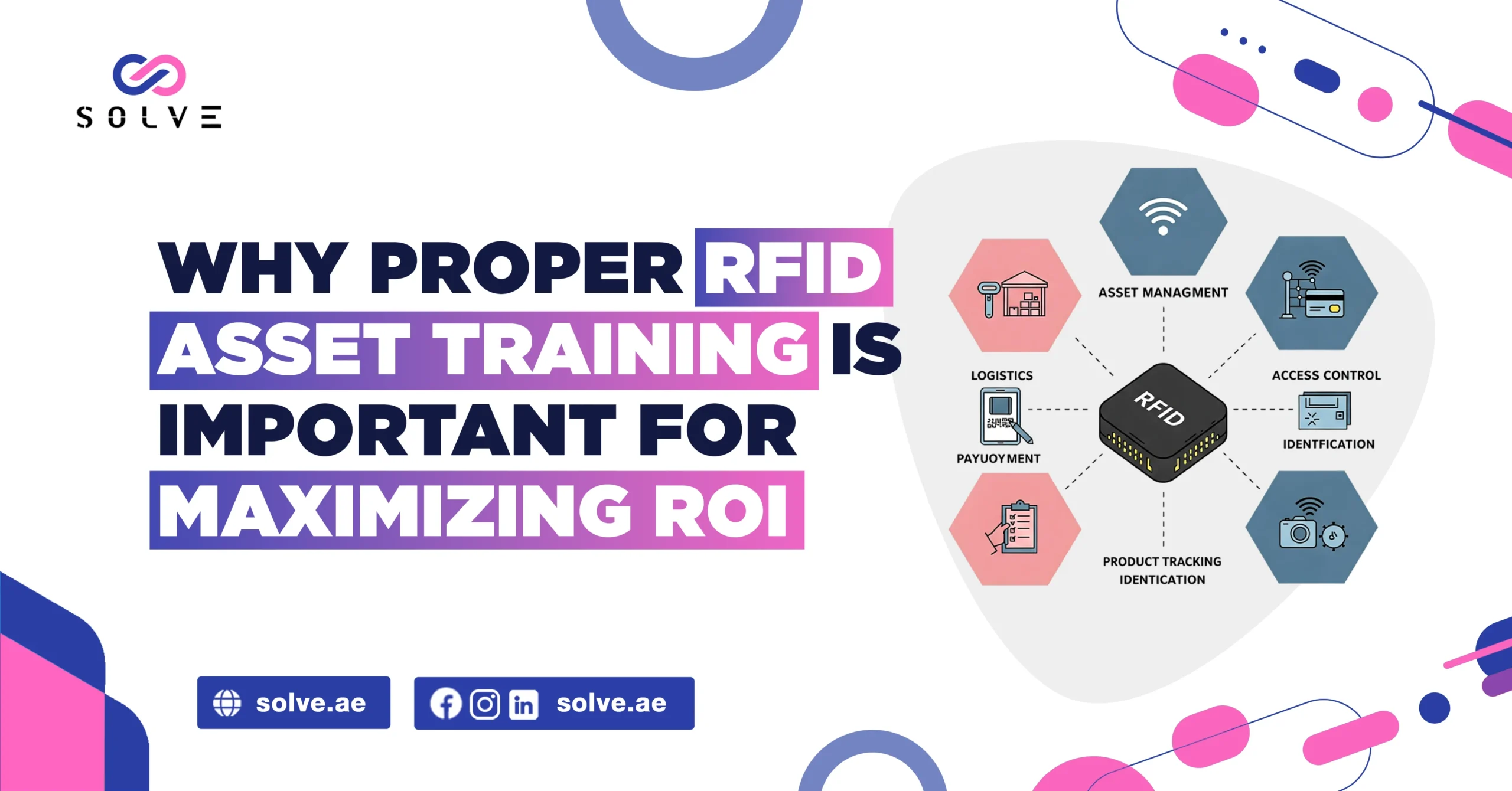

In the course of time, Radio Frequency Identification (RFID) has trended to shape asset tracking and management for businesses around the world. The companies of today are implementing it to reduce operational costs and improve performance within these widely diverse businesses. However, the success of an RFID implementation depends not only on the technology involved but, more importantly, on well-trained personnel, which usually affects whether the organization has realized the expected ROI.

The learn about RFID Technology and Its Possible ROI

The use of transponders or tags enables automatic, remote identification of things tagged with RFID transponders. These very small tags can attach themselves to or be inserted into products, equipment, or other assets for tracking and monitoring purposes, unlike conventional bar codes that require line-of-sight scanning. RFID has multiple tag read capabilities, which is an added advantage concerning speed and efficiency.

With all the prospective profits of ROI gained from RFID, it has been found that RFID systems derived between a 10% increase in productivity and output in warehouse and distribution, improved retail and point-of-sale productivity gains of 20%, and reduced out-of-stock items by up to 50% and thus reduced inventory shrinkage to 18% and more. Such effective figures translate into tangible benefits such as fast delivery, increased sales, and reduced loss.

Not just installing technology but requiring intensive training for all personnel is significant to achieve the ends.

Lack of Implementation and Adoption Gap

Most organizations have invested a lot of money in implementing RFID technology, but they do not have enough funding for training. Such conditions create a gap between implementation and optimization. Lack of training leads to employees not understanding how to use the system effectively; therefore, errors will occur, which will culminate in an inefficient process, ultimately leading to a decreased ROI.

Imagine that a manufacturing organization has planned to have an advanced RFID system in the production line for tracking work-in-progress at all stages. The company corrects the state in terms of technology setup but gives minimal instructions. The result is a high failure rate of the system and an incorrect counting of inventories, taking away many of the anticipated benefits of such an investment.

This happens almost everywhere; hence, RFID training is comprehensive, expensive, and virtually mandatory to derive optimal ROI.

The essential elements of an RFID training program are

Technical Understanding

Everyone concerned has to be versed in RFID fundamentals for effective training. This includes the meanings of different tags (active vs. passive), their frequency ranges and read ranges, and the factors that would affect tag readability.

The technical training also covers the understanding of different components in the system architecture, which would be the relationship between tags, readers, antennas, and back-end software systems. This will help in troubleshooting the identified issue and thus contribute to better system performance.

Operational Procedures

These could be proper placement of tags, strategic positioning of readers, and maintenance protocols for the system. For example, the integrative worker of an organization needs to know how to put tags on different asset types in a warehouse, as well as how to position the items to achieve the best read rates.

Management and Analysis of Information by Data

Data generated by RFID technology is its most valuable strength. Unfortunately, this data will have been generated to become insignificant unless employees are equipped with ways to create, read, interpret, and put all that data into action. The staff should also be trained in how to use data management tools and reporting functionality through analytical techniques.

Employees should be using RFID data to spot trends, recognize inefficiencies, and make decisions that are based on the data. As an example, the staff in a retail environment may use RFID to determine and analyze product movement patterns and, accordingly, adjust a layout in the store to make it optimized for the sales process. Such analysis has brought incredibly favorable ROI to an RFID installation.

Training Impact on ROI Metrics

The circuits that link proper training to key ROI metrics:

Time Reduction for Implementation

Well-trained groups can thus complete RFID systems much faster, with fewer mishaps. They know what is at stake and can foresee possible troubles even before they arise. In this way, the time between installation and operational readiness will shorten, prompting the organization to reap the benefits much earlier.

Greater accuracy of the system:

Using RFID significantly improves the accuracy of systems. Good tag placement and reader positioning by employees increases reading rates and decreases errors. Thus comes the count of more reliable inventories, fewer stock outages, and improved visibility of assets. Studies also show investments in RFID systems as being highly returnable because of their capability to be speedy and accurate in the capturing of real-time asset tracking information.

Specific Role Training

Differently, each will require training at varied levels and kinds. In the training of system administrators, detailed and intensive technical knowledge of the system is important, while warehouse staff would require operational procedure training. Creating a role-based training program ensures that the employee gets the most relevant education applicable to their role.

Hands-on Training

Theoretical knowledge may be important, but skills can only be honed through hands-on experience with the use of RFID technology. Practical exercises simulating real-world situations should be included in training programs. These might include setting the readers up, attaching tags to different types of assets, and troubleshooting common problems.

MICRO-CONTINUOUSNESS

Thus, training should be continuous and not with a single touch. Regular refresher courses and updates on new features help keep employees knowledgeable and eventually allow the organization to utilize the maximum potential of the system. check out our latest blog post on Best practices for Enhancing Supply Chain Visibility with RFID Technology

Measuring Effectiveness of Training Programs:

It should have good measures for evaluating effectiveness because it is necessary that training delivers results. This will help companies improve their training, proving a direct relationship between training and ROI.

Purpose: To Analyze Some Case Studies and Show the Impact of Training on the ROI

The organizations that invested in full RFID training saw their ROI magnified. The case in point is that of a pharmaceutical company that established a track-and-trace RFID system for its supply chain. Hence, with these advantages combined, in less than 12 months, they were able to achieve ROI far below the average industry period of 12-18 months.

Conclusion

There is massive potential for RFID to assist in asset tracking, operations, and fostering business growth. However, converting the promise into potential profit means turning to something other than just engaging with the technology. Contact us as training of end-users to use the RFID systems, to maintain them, and to create maximum optimization thereof remains an important component.

Remember, really, RFID’s worth comes not from the technology but rather from how well your people can use that technology. Training is the key that opens the door to this value, making RFID from a tracking tool into a strategic asset that will give you a sustainable and significant return on the investment.